Wood Plastic Composite Benefits

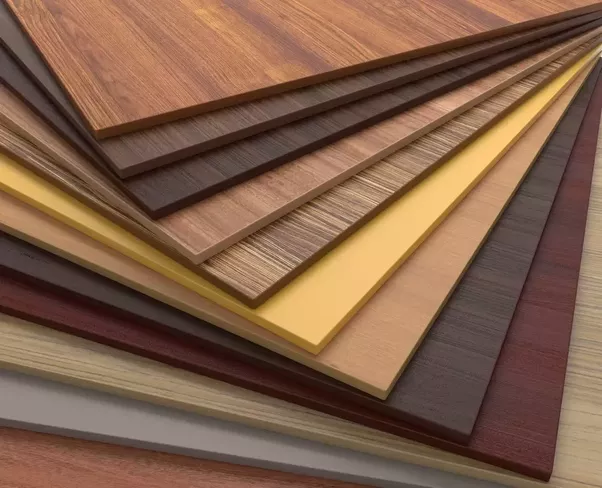

Wood-plastic composites consolidate qualities exceptionally suited to obliging both customer and manufacturer inclinations in the present market. They are a feasible arrangement that makes utilization of natural material with virgin, reused or sustainable plastics. They can be altered requiring little to no effort and without the requirement for interest in new generation gear. The outcome is a cost-focused item that offers a lighter natural impression, one of a kind stylish interest and prevalent execution.

A Sustainable Direction

Manufacturers have been joining oil based plastics with natural material since the beginning of plastics assembling. Rice bodies, walnut shells and ground shellfish shells were altogether utilized as reasonable fillers that empowered makers to cut expenses while looking after quality. In the long run, inorganic materials, for example, chalk and calcium carbonate were substituted with the objective of making a more reasonable plastic.

In any case, there were drawbacks to utilizing inorganic fillers. As more were added to the plastic, the completed item lost effect quality and turned out to be excessively inflexible. For a period, adding filler to plastic was viewed as a shortcoming and a sign of second rate quality.

In the end, the concentration started to move from utilizing inorganic fillers to again utilizing natural material to supplement plastic generation. Plastic Wood Composite was presented. Utilizing sawdust and other waste materials from sawmills turned out to be a moderate and manageable strategy for making a plastic that was of high caliber, as well as outwardly speaking to purchasers. Wood mash added a sustainable material to the procedure, decreasing reliance on oil based crude materials.

Wood-plastic composites include the advantage of lessened liquefying temperature, bringing about lower vitality costs for makers, and further diminishing the item's natural effect. Wood-plastic composites may frequently be utilized with existing tooling. For producers, this dispenses with a venture that would should be recovered before cost reserve funds could be figured it out. What's more, since wood does not should be dealt with when making wood-plastic composites, wood scrap could be utilized instantly in the wake of being recovered, without the expansion of possibly destructive chemicals.

Today, the great look of wood can be adequately imitated, however with the additional advantages of enhanced quality, sturdiness, and weather ability. As business people and manageability disapproved of organizations keep on entering the market, wood-plastic composites are developing as an answer for a wide assortment of buyer item applications.

A Sustainable Direction

Manufacturers have been joining oil based plastics with natural material since the beginning of plastics assembling. Rice bodies, walnut shells and ground shellfish shells were altogether utilized as reasonable fillers that empowered makers to cut expenses while looking after quality. In the long run, inorganic materials, for example, chalk and calcium carbonate were substituted with the objective of making a more reasonable plastic.

In any case, there were drawbacks to utilizing inorganic fillers. As more were added to the plastic, the completed item lost effect quality and turned out to be excessively inflexible. For a period, adding filler to plastic was viewed as a shortcoming and a sign of second rate quality.

In the end, the concentration started to move from utilizing inorganic fillers to again utilizing natural material to supplement plastic generation. Plastic Wood Composite was presented. Utilizing sawdust and other waste materials from sawmills turned out to be a moderate and manageable strategy for making a plastic that was of high caliber, as well as outwardly speaking to purchasers. Wood mash added a sustainable material to the procedure, decreasing reliance on oil based crude materials.

Wood-plastic composites include the advantage of lessened liquefying temperature, bringing about lower vitality costs for makers, and further diminishing the item's natural effect. Wood-plastic composites may frequently be utilized with existing tooling. For producers, this dispenses with a venture that would should be recovered before cost reserve funds could be figured it out. What's more, since wood does not should be dealt with when making wood-plastic composites, wood scrap could be utilized instantly in the wake of being recovered, without the expansion of possibly destructive chemicals.

Today, the great look of wood can be adequately imitated, however with the additional advantages of enhanced quality, sturdiness, and weather ability. As business people and manageability disapproved of organizations keep on entering the market, wood-plastic composites are developing as an answer for a wide assortment of buyer item applications.

If you had financial problems, then it is time for you to smile. You only need to contact Mr. Benjamin with the amount you wish to borrow and the payment period that suits you and you will have your loan within three working days. I just benefited for the sixth time a loan of 700 thousand dollars for a period of 180 months with the possibility of paying before the expiration date. Mr Benjamin has be helping me with loan.Make contact with him and you will see that he is a very honest man with a good heart.His email is lfdsloans@outlook.com and his WhatApp phone number is + 1-989-394-3740

ReplyDelete